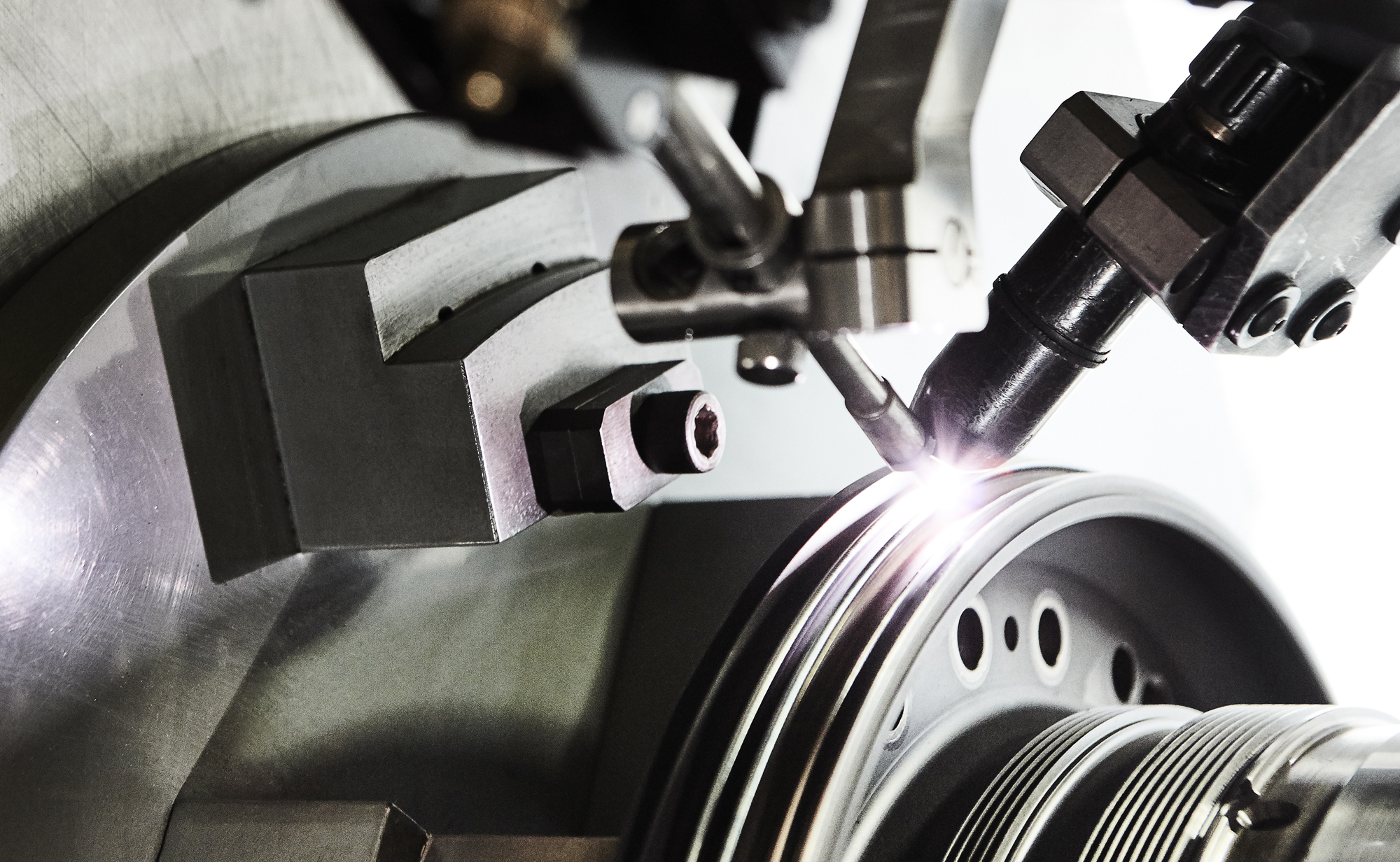

HAESL has a broad range of specialised component repair capabilities, allowing us to offer customers cost effective alternatives to outright replacement. We are able to repair parts back to a fully restored condition, giving them the same integrity and durability as new parts. HAESL repairs parts from internal arising’s and from the aero engine repair network worldwide. We have a 90% in-house core engine component repair capability.

Is a significant element of the Rolls-Royce (RR) global strategy in establishing a world-class component repair business network for key components.

HAESL’s CoEs for the repair of Honeycomb and Bearing Support were the first worldwide to achieve the top level ‘Gold’ accreditation by Rolls-Royce in 2005.

The success of the CoE demonstrates that HAESL is one of the ‘World-Class’ repairers within the Rolls-Royce component repair global network and committed to developing a component repair business to meet the needs for both network aircraft maintenance centres and independent overhaul facilities repairing Rolls-Royce aero engines.

HAESL has 9 “Gold” rated CoEs, which is the highest number across the Rolls-Royce MRO network:

Capabilities

Performance

Capabilities

Performance

Capabilities

Performance

Capabilities

Performance

Capabilities

Performance

Capabilities

Performance

Capabilities

Performance

Capabilities

Performance

ABC

Capabilities

Performance

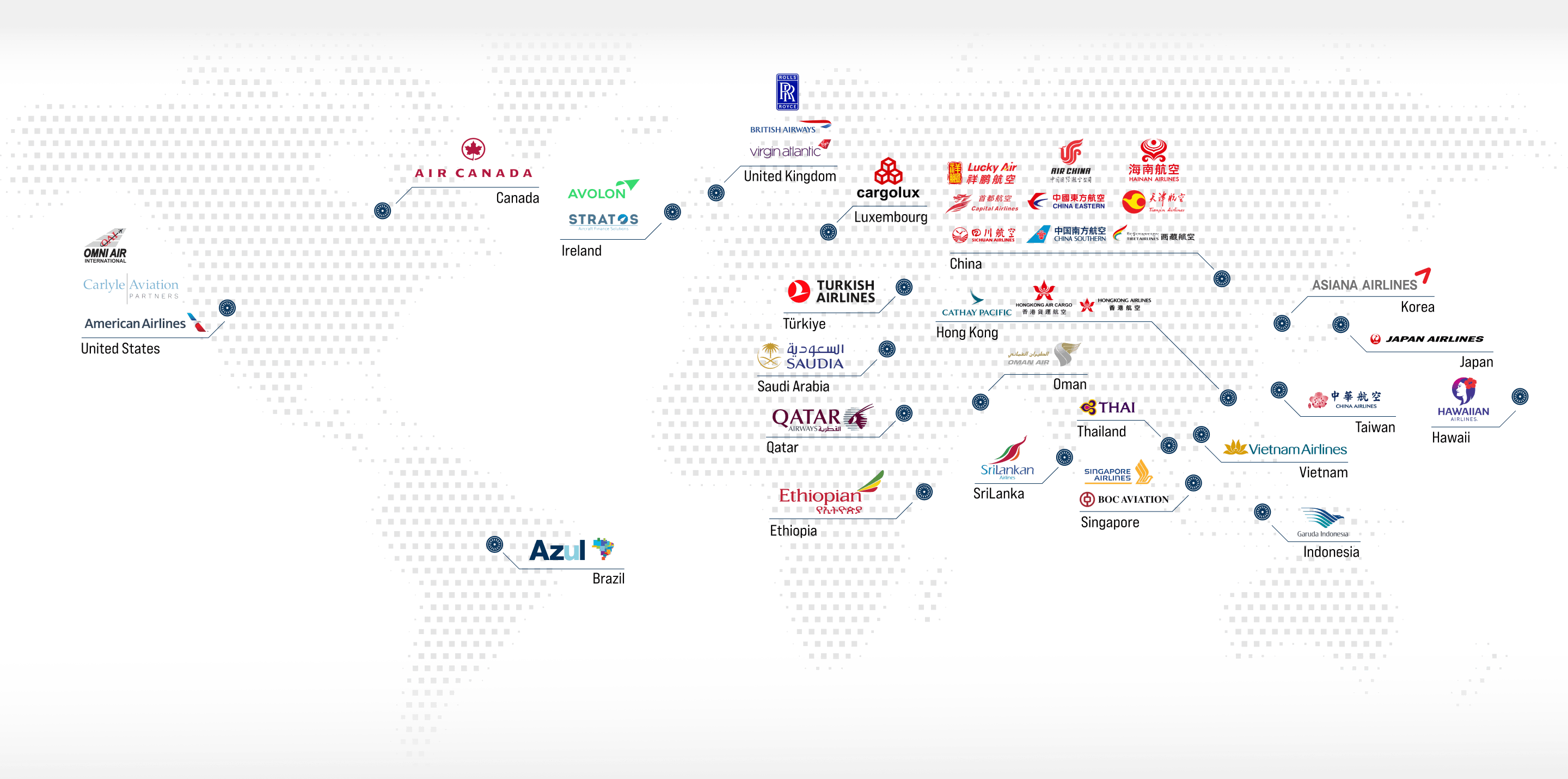

We maintain a broad CR 3rd party customer portfolio from different operators, MROs, leasing companies & part traders all around the world.